Adhesive paper on reel

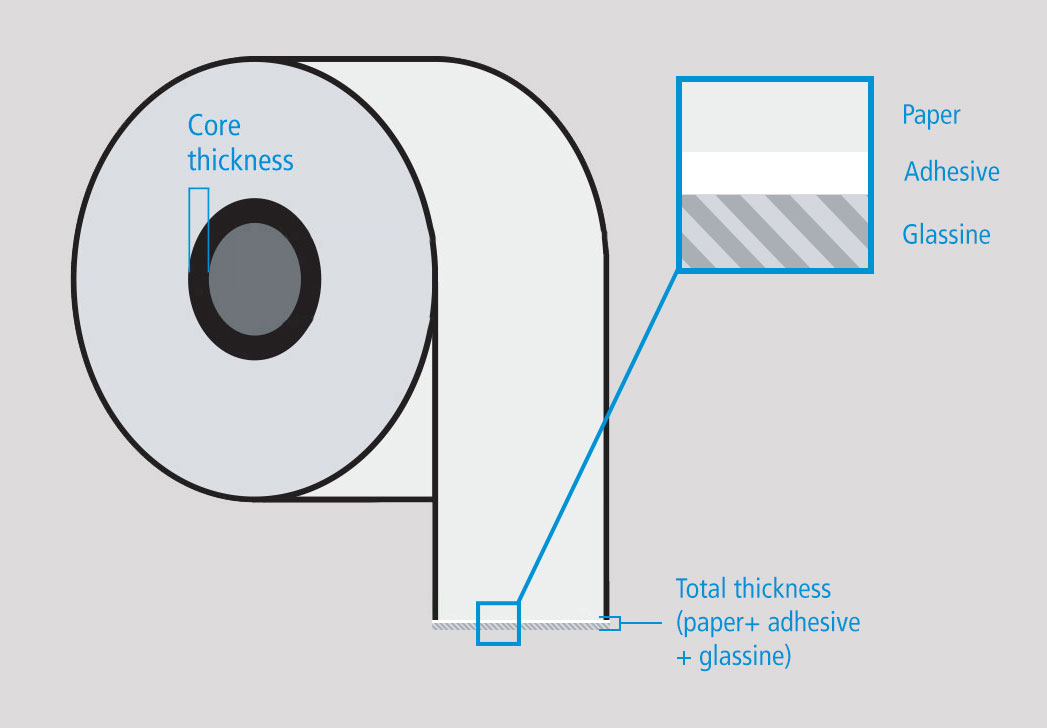

The adhesive paper on reel is the raw material on which print, finishing and packaging processes for adhesive labels are carried out. A reel of adhesive paper is made of thee merged layers: the first one (the one on the top) is made of paper, the second one (the one on the bottom) is made of a glassine that works as support for the top layer. Between the paper and the glassine layer there is a third layer made of glue.

Due to the structure of this material, for each type of adhesive paper reel it is possible to measure (in gr/mq) grammage of the front and of the back (together they determine the total weight). Also (in micron) the thickness of the front and the back (toghether they determine the total thickness). Those data are usually given by the manifacturer to the label and printing industries, and they’re useful to estimate the weight and the volume of the final product reels and optimize the delivery management to the end customer.

For now, satisfying the demand of the label industry in terms of performance of raw material and final product appearance, there are various type of adhesive paper on reel, divided by paper type and adhesive type.

The best selling paper types are the coated, natural, metallic ones, together with thermal print papers. The adhesive used for granting the adherence of the paper to the support, so the adherence of the labels to product, could be removable or not removable. They could generally have an acrilic base or polymeric natural rubber base. To satisfy the raising request of eco-friendly packaging, many paper factories begun to propose products made from recycled paper, or made from wooden paper certified by FSC (Forest Stewardship Council).

This page is part of Gerp's glossary of terms. Gerp is a dedicated MIS to packaging industry. You are welcome to browse this website or contact us for more information.