Foil consuming optimisation in hot foil printing

written August 07 2023

Hot foil printing is a set-up process whereby a metal foil is transferred through a magnesium die using a rotary cylinder machine. The application of the foil occurs through a combination of pressure, heat and release speed.

Depending on the case and the possibilities offered by the printing machine, the foil can be mounted in the direction of the paper roll or orthogonally to it. Orthogonal foil mounting is possible when the foil has a lower height and width than the label surface, and allows (when permitted) to reduce consumption and waste more effectively than traditional mounting.

When the foil is mounted in the sliding direction of the reel, conditions may occur that would allow a better optimisation of the foil.

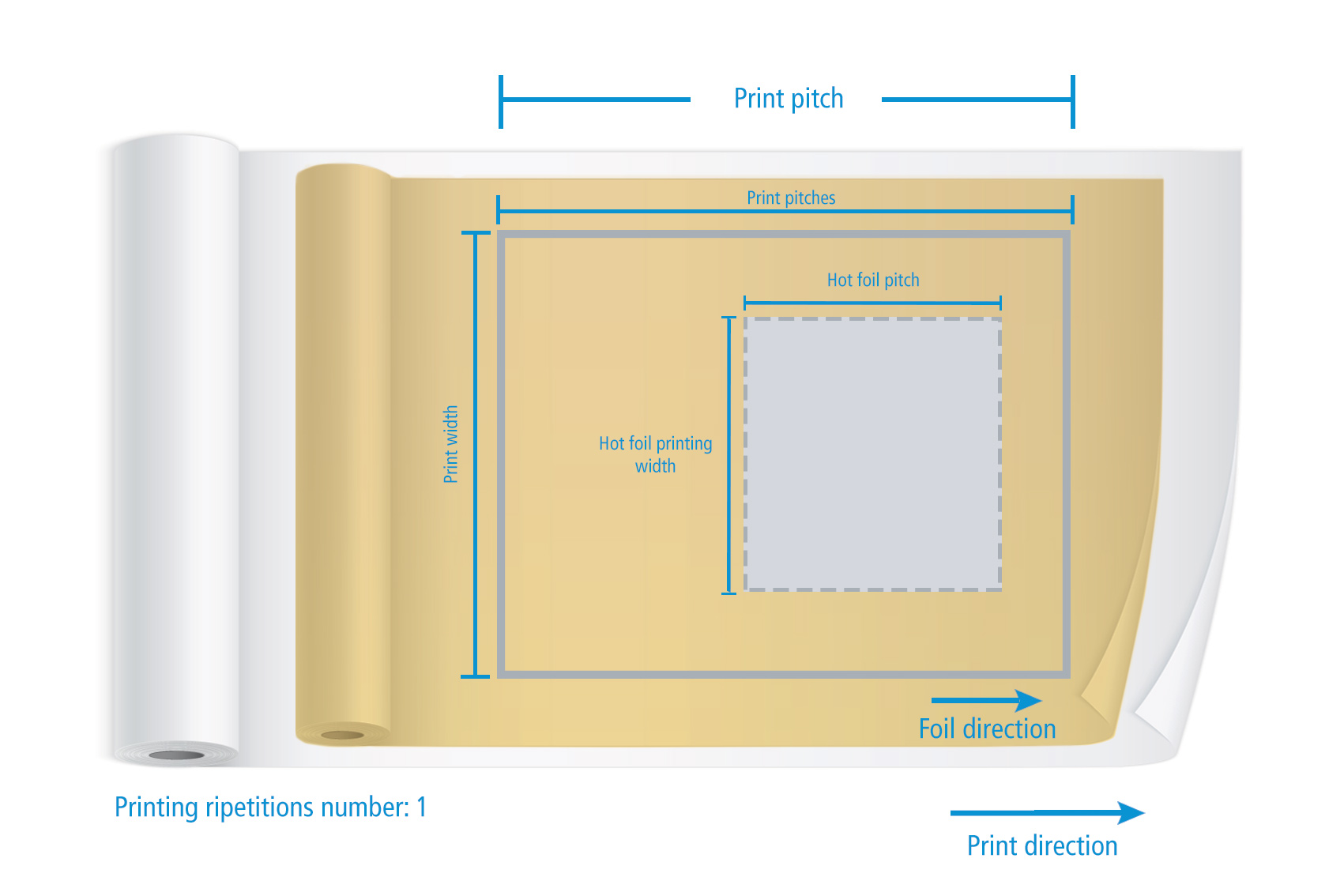

CASE A)

We have an advancing pitch and a portion of the label where the foil will be applied. In this case, if the machine allows a different hot printing speed, hot printing optimisation is always possible.

EXAMPLE: we need to print 1,000 labels that have a print format (width x pitch) of 60x100 mm and a hot stamp format (width x pitch) of 40x40 mm. In this case, the paper consumption for production will be equal to the label height (pitch) times the number of labels, i.e. approximately 100 running metres.

Similarly, since foil consumption can be optimised, this will be equal to the height of the hot-foil printing area (pitch) times the number of labels, i.e. approximately 40 metres.

Case A: Optimisable | |

Labels to be produced | 1,000 pcs |

Print label pitch | 100 mm |

Hot printing pitch | 40 mm |

Consumption of adhesive paper | 100 ml |

Consumption of hot-printed foil | 40 ml |

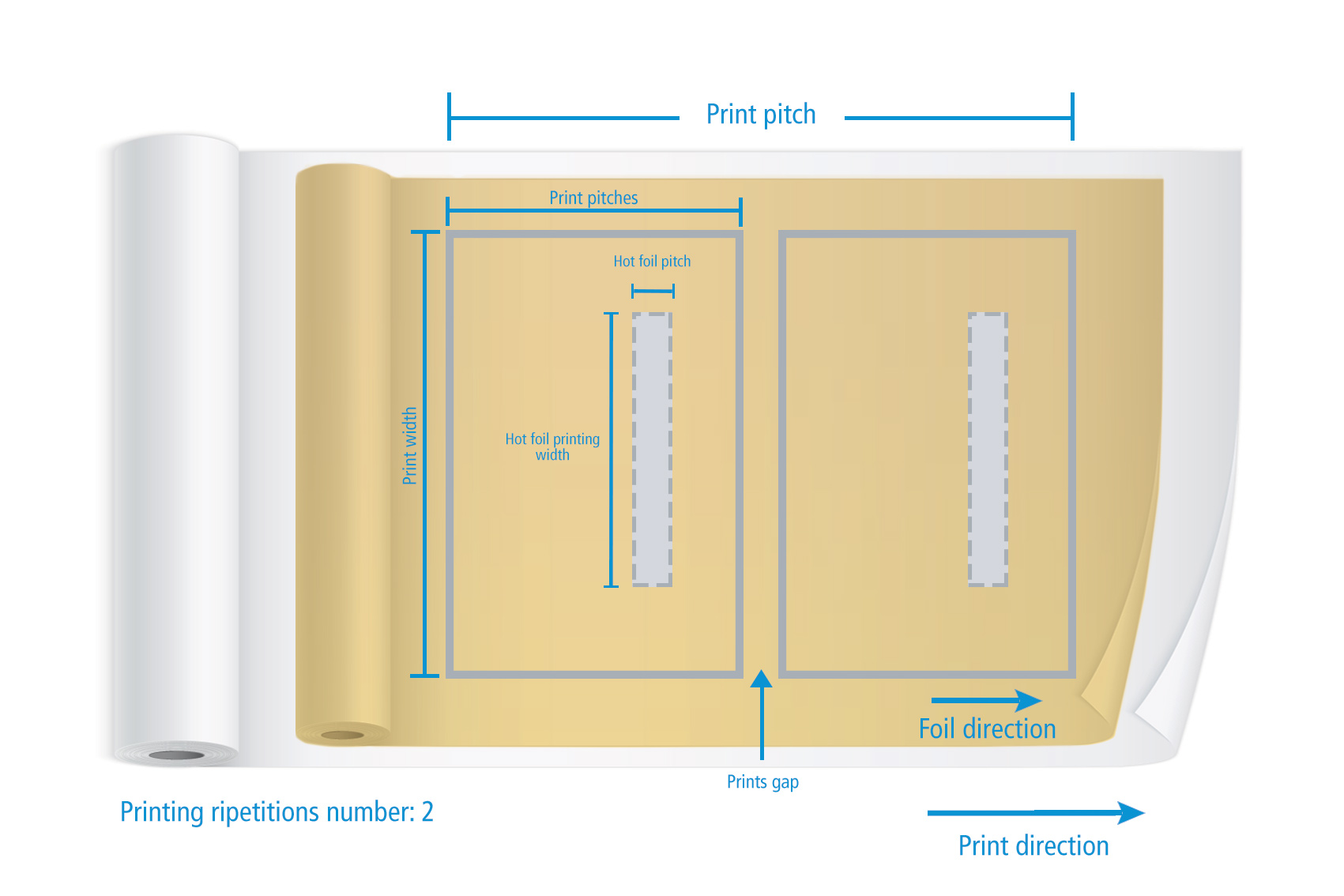

CASE B)

We are in the situation where we have several footprints advancing. In this case, foil optimisation is possible if this condition is met:

| Hot printing pitch < | Prints pitch |

| number of prints in progress |

i.e. the height of the foil (hot foil pitch) must be less than the height of the individual impression (label pitch) divided by the number of advancing impressions.

EXAMPLE: we need to print 1,000 labels with a yield of 2 impressions in advance. Each impression has a print size (width x pitch) of 100x60 mm and a hot printing size (width x pitch) of 60x10 mm each. In this case, the hot printing can be optimised because the hot printing pitch (10 mm) is less than the impression pitch (60 mm) divided by the number of feed impressions, in this case 2.

Case B: Optimisable | |

Labels to be produced | 1,000 pcs |

Printing label pitch | 60 mm |

Hot printing pitch | 10 mm |

Adhesive paper consumption | 60 ml |

Hot-printed foil consumption | 10 ml |

So we will have a paper consumption for the production of 1,000 labels of about 60 running metres and a foil consumption of about 10 running metres.

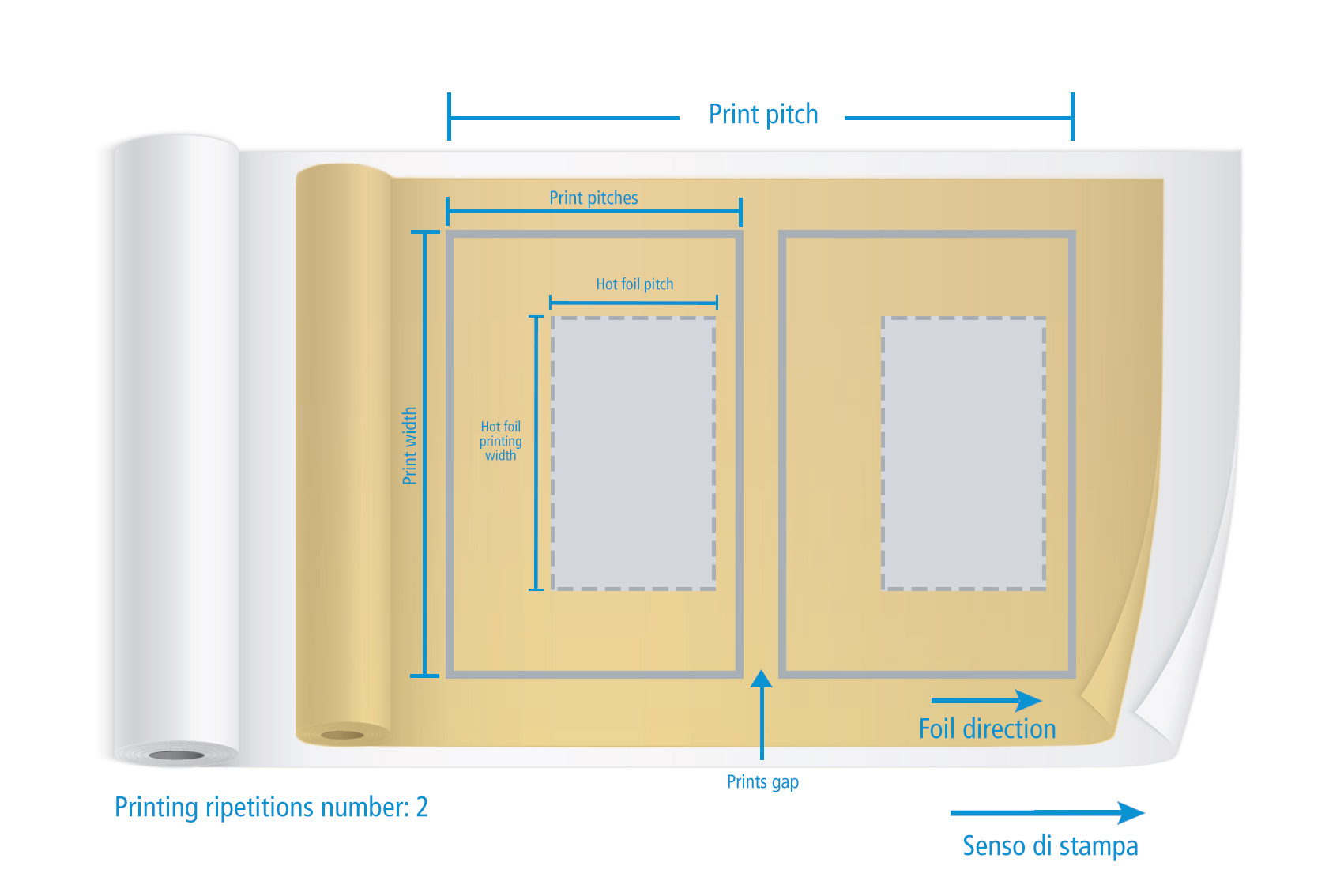

CASE C)

We are in the situation where we have more and more footprints moving forward. In this case, however, optimisation of the foil is not possible as the condition is not met:

| Hot printing pitch > | Print pitch |

| printing ripetitions number |

EXAMPLE: we always have 2 impressions in progress. Each impression has a print size (width x pitch) of 100x60 mm and a foil size (width x pitch) of 60x40 mm each. In this case, since the condition that the height of the foil must be less than the height of the individual impression divided by the number of impressions (40 mm is not less than 60/2) is not verified, the foil print cannot be optimised.

Case C: Not optimisable | |

Labels to be produced | 1,000 pcs |

Printing label pitch | 60 mm |

Hot printing pitch | 40 mm |

Adhesive paper consumption | 60 ml |

Hot printing foil consumption | 60 ml |

So the consumption of foil will coincide with the consumption of paper for the production of 1,000 labels, i.e. approximately 60 running metres.

For simplification reasons, gaps and print margins were not take in consideration.