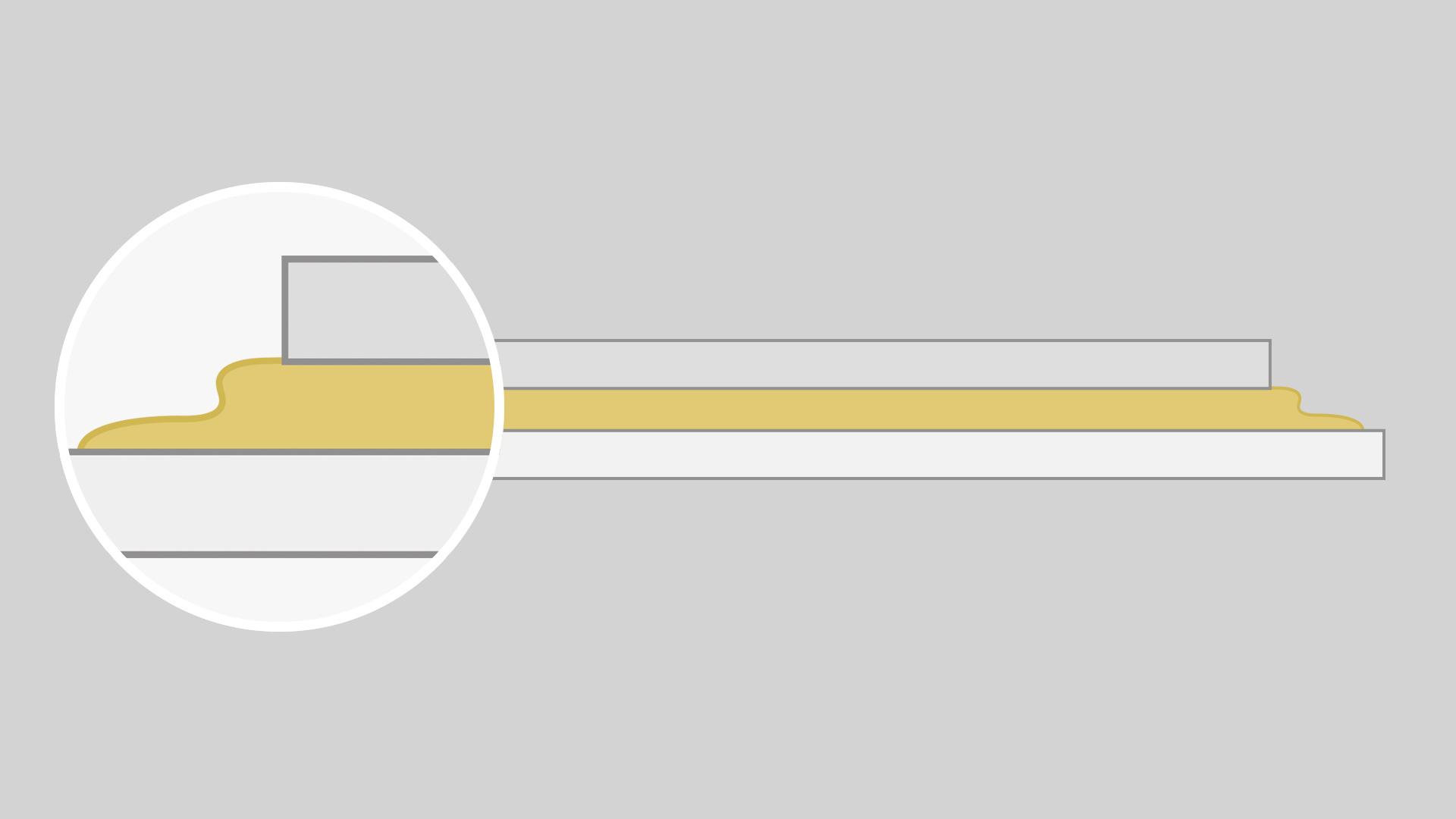

Adhesive bleed

Adhesive bleed occurs when the adhesive material on the back of adhesive paper reels or labels moves from its position, it can be caused by several factors:

Adhesive bleed occurs when the adhesive material on the back of adhesive paper reels or labels moves from its position, it can be caused by several factors:

- Rolls were stored incorrectly

- Labels roll was wrapped too tightly

- The adhesive used was too soft

- The plastic label material shrinks

- The punching tools used by the manufacturer were not sharp enough.

How to correctly store labels: mild temperatur, no pressure.

Labels should be stored at 50-60% humidity and a constant room temperature of 18-24 degrees Celsius. Rolls should not be stored on a shelf or packed tightly together. If they’re stored in close contact they might become unusable after a very short time. The pressure might push the adhesive off the edges of the label. When a roll is unwound, the labels in a particular area will stick to the back of the top holder.

After a while, increasing humidity could cause paper labels and media to swell. The pressure applied to the labels inside the roll increases continuously. This also causes the adhesive to leak off the edges. The roll sticks, hardens and can no longer be used.

This page is part of Gerp's glossary of terms. Gerp is a dedicated MIS to packaging industry. You are welcome to browse this website or contact us for more information.