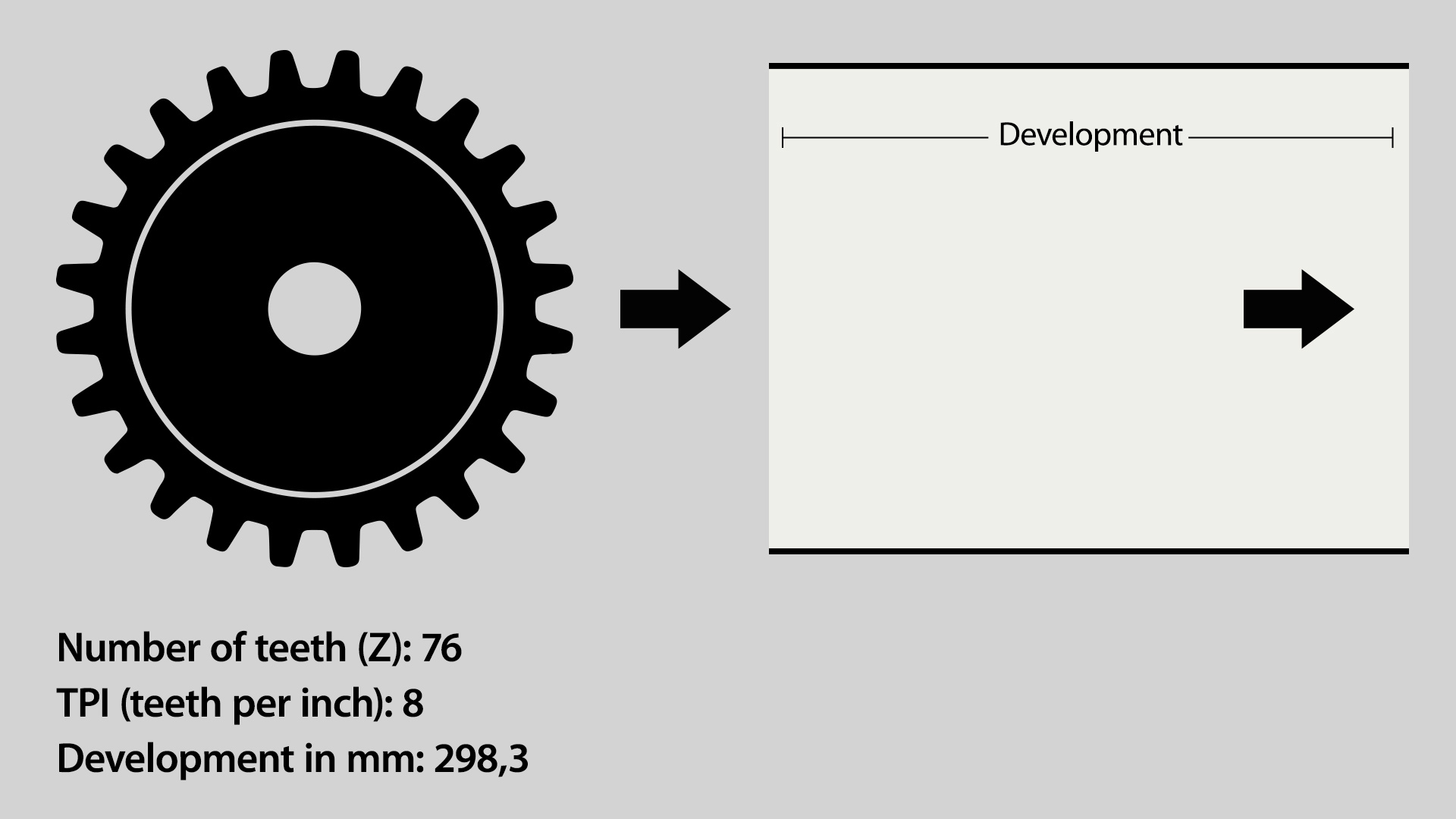

Number of gear teeth (Z)

The number of teeth (denoted by ‘Z’) is the number of projections found on each of the gears in rotary printing presses. A gear is a toothed component of the machinery, similar to a cog or cylinder, that meshes with other parts of the same structure to transmit motion, change speed or direction to the work being performed by the machinery. Gear dimensions can be measured in inches (TPI, teeth per inch) or centimetres (TPM, teeth per centimetre).

By convention, the teeth of rotary machine gears measure 3.175 centimetres. The number of teeth also defines the development of the cylinder, the more teeth there are on the surface of the gear, the greater its development. In a rotary printing press, it is necessary to know the dimensions of the gears that can be installed because they determine the dimensions of the plates and equipment used for printing, and consequently the repetitions of the labels that can be placed side-by-side in the same stop (a Z 96 plate can only be used if the machine is designed to mount components of these dimensions).

Therefore, on a rotary machine, each stop must measure exactly as much in feed as the development of the gear fitted.

For example: if we use a Z 86 (corresponding to 273.05 cm) on the machine, each stop must measure 273.07 cm in feed.

On the contrary, in a semi-rotary machine the development of the stop is not bound to the development of the gear because this type of machine is designed to use even fractions of its development (the movement of a semi-rotary machine does not have to be continuous but can be intermittent). For example: if the gear of a semi-rotary machine measures Z 90 (285.75 cm), the forward extension of each stop does not necessarily have to measure 285.75 cm, but can develop more or less centimetres with respect to this value.

| Table Z - eighths of an inch | |||

| Development in mm | Conversion factor | Development in inches | |

| 68 | 215.9 | 3,175 | 8" 1/2 |

| 69 | 219.075 | 3,175 | 8" 5/8 |

| 72 | 228.6 | 3,175 | 9" |

| 80 | 254 | 3,175 | 10" |

| 88 | 279.4 | 3,175 | 11" |

| 90 | 285.75 | 3,175 | 11" 2/8 |

| 94 | 298.45 | 3,175 | 11" 6/8 |

| 102 | 323.85 | 3,175 | 12" 5/8 |

Gerp provides a free tool to calculate the optimum roller (Z) from the print size.

This page is part of Gerp's glossary of terms. Gerp is a dedicated MIS to packaging industry. You are welcome to browse this website or contact us for more information.