The Importance of a Machinery Maintenance Plan for a Production Company

written March 29 2023

Machinery maintenance is crucial for any production company that wants to ensure the continuity of its operations. In this article, we will explore the importance of a machinery maintenance plan for a production company and provide some guidelines for its implementation.

Why is a machinery maintenance plan important?

Reduced production costs: One of the primary reasons why production companies invest in a machinery maintenance plan is to reduce production costs. Regular machinery maintenance can help prevent costly breakdowns and lengthy downtimes, increasing the efficiency of production processes and the production of high-quality products.

Increased machinery lifespan: Regular maintenance can also prolong the lifespan of machinery, preventing it from deteriorating and becoming obsolete too soon. This means that production companies can avoid costly machinery replacements too frequently.

Improved safety: A regular maintenance plan can also contribute to improving safety in the workplace. Machinery that has not been properly maintained can pose a safety risk to workers, and the implementation of a maintenance plan can reduce this risk.

Regulatory compliance: Many production companies are subject to regulations and standards concerning machinery maintenance. Non-compliance with these regulations can result in fines and penalties that can be avoided with the implementation of a maintenance plan.

Guidelines for implementing a machinery maintenance plan:

Identify machinery that requires maintenance: The first step in implementing a machinery maintenance plan is to identify machinery that requires maintenance. This can be done through analysis of production activities and historical data on machinery maintenance.

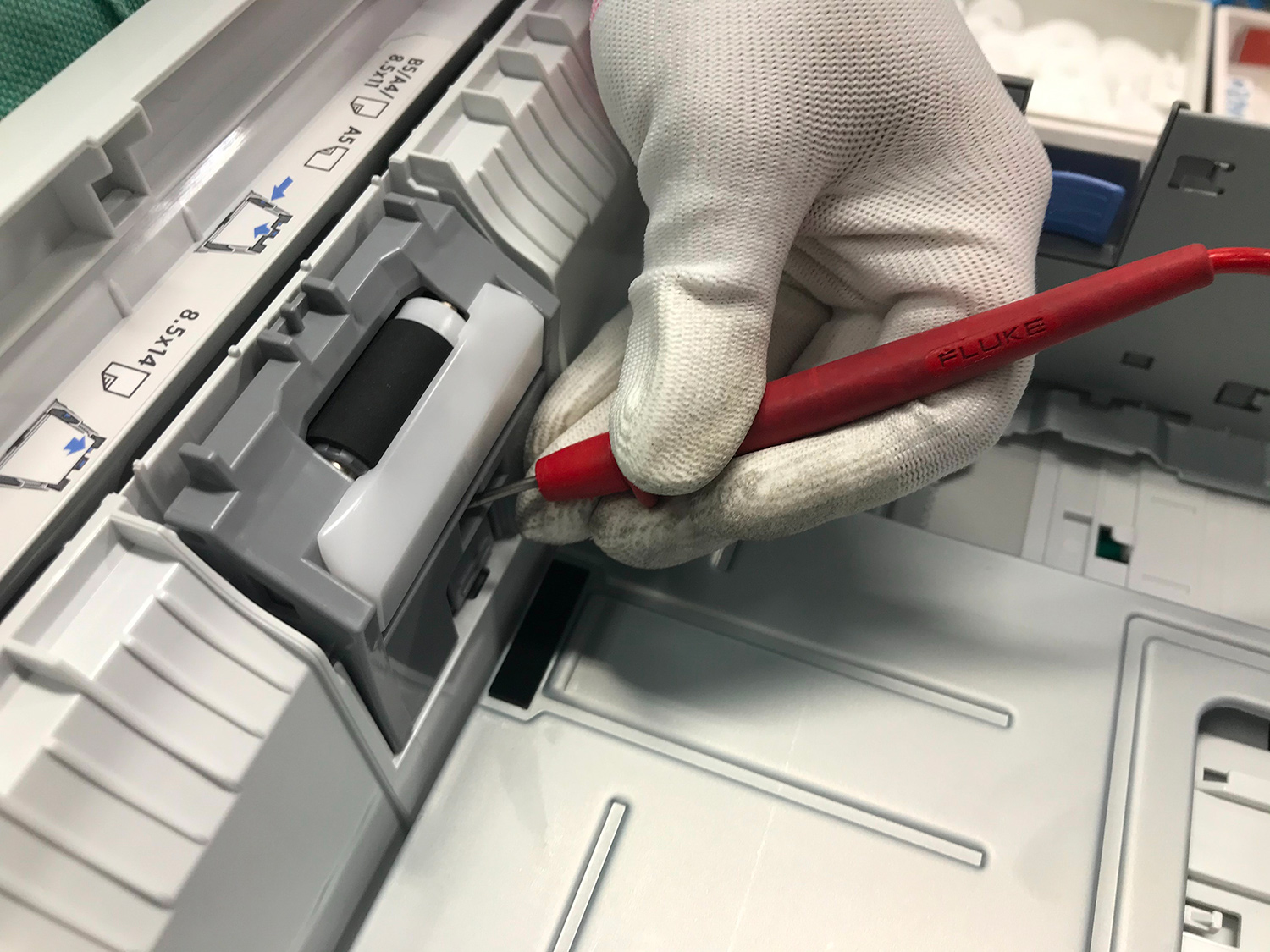

Determine necessary maintenance activities: Once machinery requiring maintenance has been identified, it is necessary to determine the necessary maintenance activities for each piece of machinery. This can include part replacement, cleaning, lubrication, and checking safety systems.

Establish a schedule: After determining necessary maintenance activities, it is important to establish a schedule for executing these activities. This can be done through the creation of a maintenance calendar, indicating when maintenance activities need to be executed and by whom.

Monitor and record maintenance activities: Once the maintenance plan has been implemented, it is important to monitor and record maintenance activities. This can be done through a maintenance log, which records maintenance activities executed and identifies any trends that may emerge.

A machinery maintenance plan is a critical element for any production company that wants to ensure the continuity of its operations. Regular machinery maintenance can contribute to reducing production costs, prolonging machinery lifespan, improving safety in the workplace, and ensuring regulatory compliance. Implementing a maintenance plan requires accurate analysis of machinery, determination of necessary maintenance activities, creation of a schedule, and constant monitoring of executed maintenance activities. Investing in machinery maintenance is a significant investment that can bring great long-term benefits to the production company.